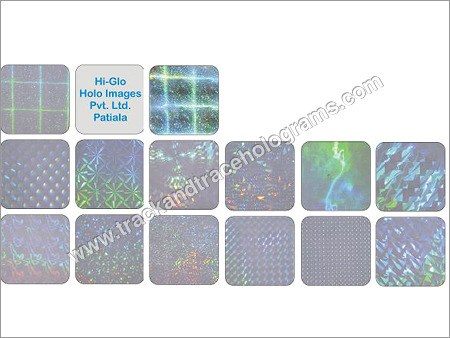

Transparent Holographic Films

Price 4 INR/ Sheet

Transparent Holographic Films Specification

- Color

- Grey

- Shape

- Other

- Thickness

- 12-150 Microns Millimeter (mm)

- Feature

- Self-Adhesive

- Type

- Holographic Films

Transparent Holographic Films Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 10 Days

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, Eastern Europe, Middle East, Central America, South America, Africa

- Main Domestic Market

- All India

About Transparent Holographic Films

Capitalizing on our talented workforce and sound amenities, we are manufacturing and exporting a wide gamut of Transparent Holographic Films. Offered in tamper and non tamper range, these films are manufactured using optimum quality materials and modern technology under the guidance of skilled professionals. Owing to attributes like longer shelf life, smooth finish and durable design, our Transparent Holographic Films are extensively used for the purpose of packaging, decoration and promotion of products.

Further Details:

Non tamper evident holographic stickers hologram image wont be damaged when its torn off from surface on which it is pasted such as paper, glass and plastic card etc. These are offered in the competitive prices.

Versatile Self-Adhesive Holographic Films

Designed for hassle-free application, our self-adhesive transparent holographic films in grey are crafted to provide a stylish and secure overlay on a range of surfaces. Their square shape ensures uniform coverage, while thickness options from 12 to 150 microns accommodate lightweight decorations to robust protective layers. These films are ideal for branding, point-of-sale displays, and gift packaging.

Expertise from an Indian Industry Leader

With extensive experience as a manufacturer, supplier, and exporter in India, we deliver high-quality holographic film solutions that meet domestic and international standards. Our commitment to innovation and quality control makes us a preferred partner for businesses looking for reliable and attractive film materials.

FAQs of Transparent Holographic Films:

Q: How can Transparent Holographic Films with a grey color be used in commercial applications?

A: These films are often used in packaging, branding materials, window displays, and decorative overlays due to their appealing visual effects, transparency, and ease of application.Q: What process is involved in applying self-adhesive holographic films?

A: Application involves cleaning the target surface, peeling off the films backing, and carefully pressing the adhesive side onto the surface, ensuring smooth attachment without bubbles.Q: When should I choose a thickness between 12 to 150 microns for my project?

A: Choose thinner films (12-30 microns) for lightweight applications like labels, and thicker films (up to 150 microns) where more protection or structural integrity is required, such as packaging overlays or secure branding.Q: Where are your holographic films manufactured and available for export?

A: Our films are manufactured in India with strict quality standards and are readily available for export to international markets, as well as for distribution domestically across India.Q: What are the main benefits of using these transparent holographic films?

A: Key benefits include enhanced visual appeal, easy and secure self-adhesive application, customizable thickness, durable protection, and suitability for diverse decorative or branding needs.Q: How do you ensure consistent quality across your holographic film products?

A: Quality control is maintained through rigorous testing and inspection during manufacturing, ensuring each batch meets industry benchmarks for clarity, adhesion, and durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Holograms Category

Dot Matrix Holograms

Price 0.10 INR / Unit

Minimum Order Quantity : 150000 Pieces

Hardness : Soft

Color : Multicolor

Customized : Size, Color, Shape, Logo

Type : Single Side

Scratch Off Coupon Or Cards Sample

Minimum Order Quantity : 1000 Pieces

Hardness : Rigid

Color : Multicolor/design customizable

Customized : Size

Type : Other, Scratch Off Coupon Or Cards

Hologrammed Shrink Sleeves

Price 4 INR / Sheet

Minimum Order Quantity : 10000 Pieces

Hardness : Rigid

Color : White and Silver

Customized : Size, Color, Style, Logo

Type : Shrink Sleeves

Pharma Hologram Seals

Price 5 INR / Sheet

Minimum Order Quantity : 10000 Pieces

Hardness : Rigid

Color : Blue and White

Customized : Size, Style, Logo, Color

Type : Single Side

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry